TEST Air.en Engine 150 ccm

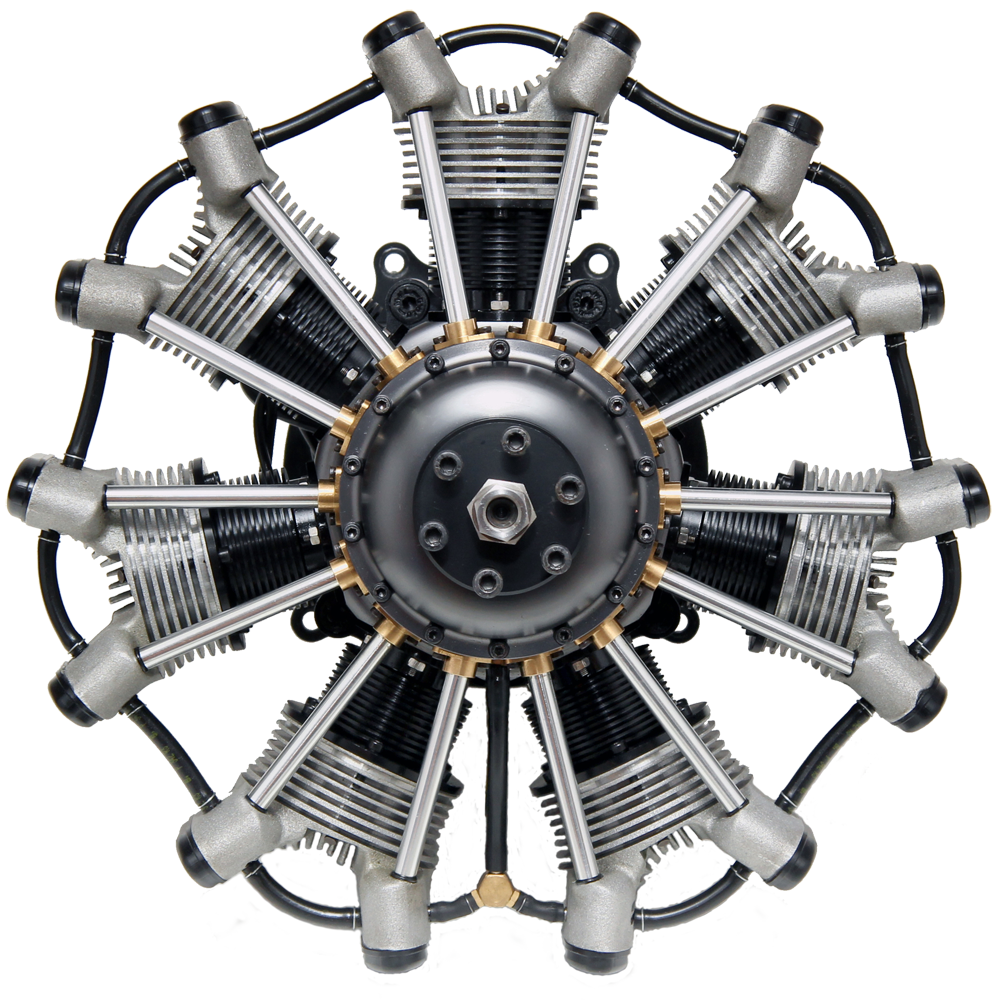

Air.en 7-cylinder radia engine 150 ccm

In the middle of 2015 we became aware of Air.en on the internet. We liked their radial engine design right from the start, as they are built similar to our Heilemann radial engines. So we got in contact with Air.en.

Luigi Spalla, once SL Engines, was very happy about our message. A few years ago, we were already in contact with SL Engines in Italy. However, a business relationship never came about. Now, after several e-mails and exchange of ideas, we suggested to Luigi Spalla to sell his radial engines and build up a repair service in Germany. We would like to offer the same service for Air.en radial engines as for our usual HS Service: advice before and after the purchase, sale and service as well as repair work -> everything in one hand!

So on July 25, 2016 we arranged an on-site appointment at Air.en Engines in Italy. We were greeted very warmly by Luigi Spalla and his assistant. His company is very well structured, organized and tidy. We were very impressed. Before, we had already ordered an engine with an electric starter and two piston rings for the operation with pure gasoline and dry sump lubrication.

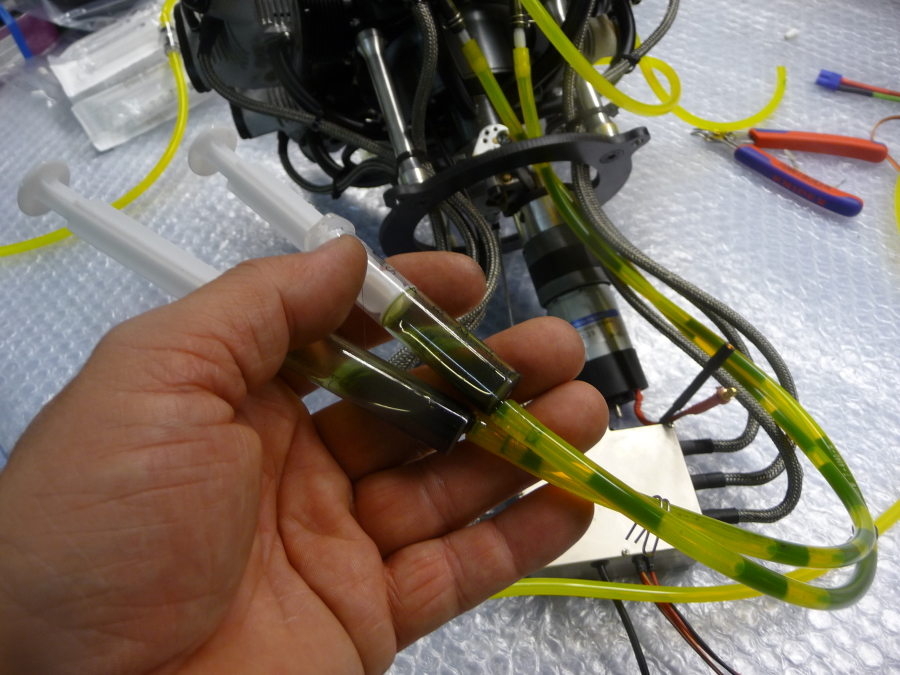

Here are a few photos of our tests:

As the engines are delivered without ring exhaust silencer and Air.en does not offer one, we built the prototype ourselves. Then we could also operate a smokepump.

The manufacturer had only sent a sketch without detailed information. So moving the dry sump lubrication was more complicated than we had anticipated. Information about the size of the oil tank, ventilation, cross sections, etc. could not be found. So we reconsidered the whole concept and decided to work with two pumps: a supply and a return line pump as well as an oil separator with crankcase breather for stunt flying. We also redimensioned the oil pipes cross section. Various oil filters had to be installed as well, because the oil pumps react very sensitively to dirt. By now it is working reliably. Our conclusion: very complex and expensive. During flight we will see whether it is worth it or just remains a gadget.

Our trial plane is a Boxfly from PAF with 3,40 m wingspan. We modified it slightly.

Starting it is a lot of fun with perfect functionality. We built a rechargeable battery into the model, so we can also start it in the air. Currently the engine is in its optimization phase to offer a real realiable radial engine. After finishing our flying season successfully and our tests, we are planning to include the engines into our radial engine assortment, including our HS service.

We stick to it and will report ...

First test flights

The preparation is finished. Fuel and oil are refuelled.

Talk shop, discussions and curious looks. Much technology is related to dry sump lubrication.

... and up into the sky!

We are flying with a SEP scale prop 30 x 10“ at 4900 rpm. In the air the engine increases at least 600 – 800 rpm. The carburetor provides full power at ¾ stick position already. Therefore we programmed a gas curve to get soft engine control.

Minor disadvantage is that the carburetor cannot be adjusted during motor run time, because the nozzle needles are positioned downwards. It is feasible with several trials by stopping the engine.

After the first flights we checked fuel consumption. It is just 200 ml for 10 min at mainly full throttle. Capacity of the ignition battery 3800 mA, about 1500 mA/h

We tried to start the engine manually, even equipped with electric starter: no problem at all, immediate start.

Several test flights without any problem. Reliable functionality. Pilot is smiling! The engine is working hard to handle 23.8 kg model weight. Scale flying is the right style. Please have a look to more pictures in our picture gallery, with Robin Trumpp as pilot.

More test flights will go on.

After approx. 10 hours of flying without any problems, the engine at low idle speed decreased significantly, the rpm collapsed. On top of that, it started vibrating strongly at low idle. After disassembly and inspection in our work shop we found out that the ignition was faulty. After consultation with Air.en we found out that there is the same problems with the ignition but no solution to offer.

So we, in cooperation with Rainbow-tronic, developed an ignition system especially for the Air.en engine.

The conversion is based on a new magnetic ring with a new sensor cable, the ignition box and special ignition electronic. For details please visit our online shop: Link

With this ignition the engine has very different running characteristics. It starts up even better, because of the ignition’s Multi-Spark function, has a very smooth idle and a powerful dynamic throttle response. At full throttle speed we are, as before, at the wanted 4200 rpm. Additionally, a speed limiter is programmed at a maximum of 5600 rpm.

In further test flights the engine has demonstrated its reliable and powerful operation. The Air.en engine is a technical master piece that amazes with its authentic appearance and reliable operation.

To our regret, we lost contact to the manufacturer in the meantime, so that we cannot sell Air.en engines at the moment.

More flights will go on!

*) zu den Fotos im Bericht: Fotografiert von H. Rebholz /geflogen von Andreas Heilemann

*) zu unserem

Video: gefilmt von Heilemann Sternmotoren /geflogen von Robin Trumpp